Choosing the Right Magnetic Roller Separator for Your Industry

2024-10-25

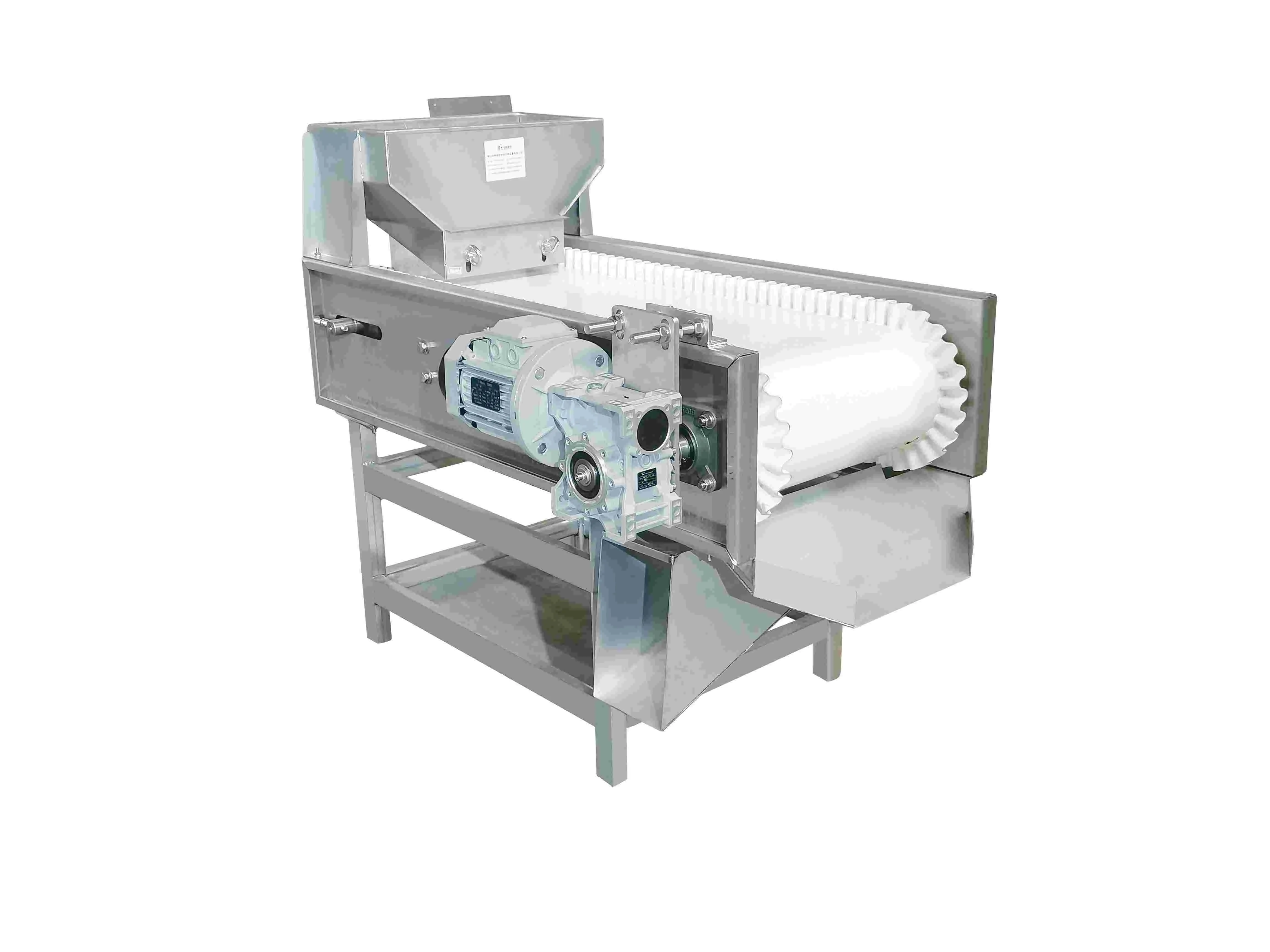

Magnetic roller separators are integral to many industries, from recycling to mining, food production, and more. But how do you choose the right magnetic roller separator for your specific needs? In this blog, we will explore the different factors to consider when selecting a magnetic roller separator, and the key features that make a system more efficient, reliable, and cost-effective.

1. Understand the Type of Material You Are Processing

The first and most important consideration is the type of material you need to separate. Different materials have varying magnetic properties, and not all magnetic roller separators are suited for every application. For instance:

- Highly Magnetic Materials: If your process involves a high concentration of ferrous materials, a powerful, high-intensity magnetic roller is ideal.

- Weakly Magnetic or Non-Magnetic Materials: Some separators are designed to separate even weakly magnetic particles from materials like glass or wood.

2. Consider the Magnetic Strength

Magnetic roller separators come in a range of magnetic field strengths, which are measured in gauss (G) or tesla (T). The higher the strength, the more efficient the separator will be at capturing ferrous particles. However, higher magnetic strength might not always be necessary. Choosing the appropriate strength depends on the type of contamination you need to remove and the material you’re processing.

3. Evaluate the Capacity of the Separator

Capacity is another vital consideration. How much material will you need to process in a given period? Magnetic roller separators come in various sizes and throughput capacities, so ensure the machine you choose can handle your production requirements. For high-volume applications, a larger drum or a multi-stage separator may be necessary to ensure efficient separation without bottlenecks.

4. Decide on the Type of Separator

There are several types of magnetic roller separators available, and the right choice will depend on the complexity of your operation:

- Single-Roller Magnetic Separators: Best for operations that need to remove small amounts of ferrous contaminants.

- Multi-Roller Separators: Provide higher accuracy for complex materials or industries that need to achieve a very high level of purity.

- Permanent Magnets vs. Electromagnets: Permanent magnets are energy-efficient and require little maintenance, whereas electromagnets offer adjustable strength but consume more power.

5. Assess the Operating Environment

The working environment also influences the type of magnetic roller separator you should choose. For instance, in wet or high-humidity conditions, separators designed for moist environments are ideal. Similarly, separators used in harsh industrial settings need to be built with durable materials to withstand wear and tear.

6. Customization and Flexibility

Some magnetic roller separators can be customized to meet the unique demands of specific industries. You may want to consider features like adjustable magnetic strength, different sizes of rollers, or specific feed and discharge methods. Additionally, the flexibility to handle different material sizes and shapes can be beneficial, especially in dynamic production environments.

7. Maintenance and Durability

Low-maintenance machines are always preferable, as they reduce downtime and operational costs. Look for separators made from robust materials like stainless steel, which resist corrosion and wear. Also, consider whether the magnetic system is self-cleaning, as this feature can greatly enhance efficiency and reduce the need for manual intervention.

Conclusion

Selecting the right magnetic roller separator depends on a variety of factors, including the material type, magnetic strength, and production capacity. By thoroughly evaluating your needs and understanding the options available, you can choose a separator that will enhance your production line’s efficiency, improve product purity, and reduce costs.

Magnetic roller separators are versatile machines that offer significant benefits across many industries. Whether you’re dealing with recycling, mining, or food production, investing in the right separator will ensure optimal performance and return on investment.