Cutting Through Possibilities: Material Capabilities and Considerations in Die Making

2023-11-30

Introduction:

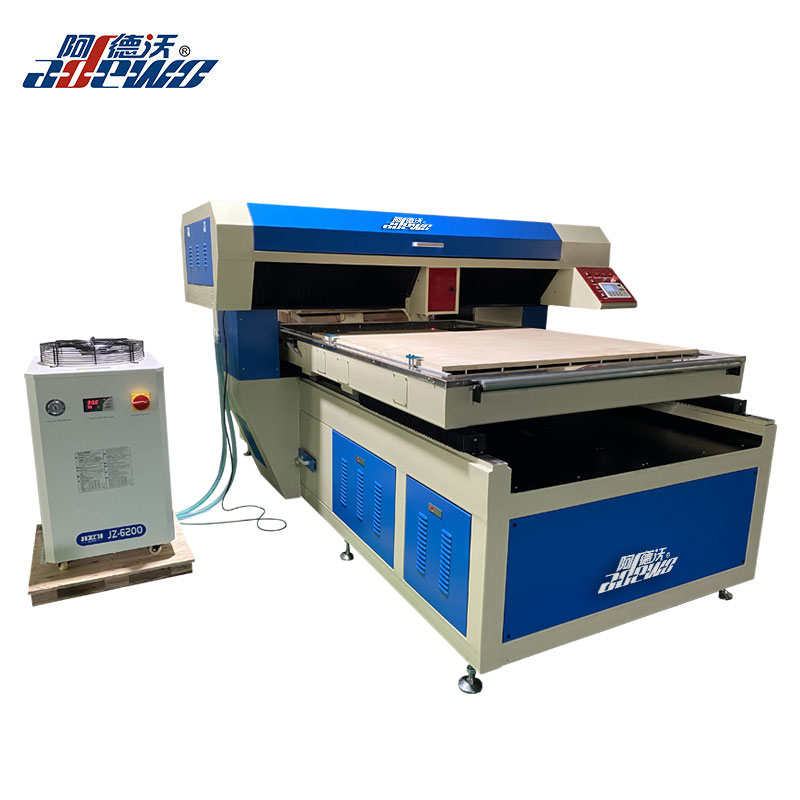

In the intricate world of die making, the choice of materials plays a pivotal role in determining the success of the manufacturing process. Our cutting-edge Die Making Laser Cutting Machine is designed to offer versatility across a spectrum of materials, ensuring that the boundaries of creativity and functionality are expanded. In this blog, we delve into the types of materials our machine can effectively cut for die making and shed light on any limitations that may exist.

1. Metallic Marvels:

Our Die Making Laser Cutting Machine is engineered to cut through a variety of metals with ease. From steel and aluminum to alloys with specific hardness levels, the precision of the laser allows for intricate designs and patterns on metal dies without compromising on structural integrity.

2. Versatility in Plastics:

Plastics, known for their diverse range of applications, pose no challenge for our laser cutting technology. Whether it's acrylics, PVC, or other thermoplastics, the machine delivers precise cuts, opening up a realm of possibilities for die makers working in various industries.

3. Exotic and Composite Materials:

In the ever-evolving landscape of materials, our Laser Cutting Machine rises to the occasion. It can effectively cut through exotic materials and composites, providing flexibility for die makers to explore innovative materials without sacrificing precision or efficiency.

4. Wood and Paper:

Die making extends beyond industrial applications, and our machine caters to artisans and craftsmen working with wood and paper. The laser's precision allows for intricate cuts in these materials, enabling the production of dies for artistic and custom applications.

5. Textiles and Leather:

For die makers working in the fashion and textile industries, our machine is a versatile tool. It can cut through textiles and leather with precision, allowing for the creation of intricate patterns and designs for garments, accessories, and more.

6. Limitations and Considerations:

While our Die Making Laser Cutting Machine offers impressive versatility, it's essential to be aware of certain limitations. Extremely reflective materials, such as highly polished metals, may pose challenges as they can reflect the laser beam. Additionally, materials with high thermal conductivity may absorb the laser energy differently, affecting the cutting process.

7. Thickness Constraints:

While our machine excels in precision, it's important to note that there are practical limits to material thickness. Thicker materials may require more power and time for cutting, and die makers should consider these factors when working with materials at the upper end of the machine's capacity.

8. Material-Specific Settings:

Different materials may require specific settings for optimal results. Our machine provides the flexibility to adjust parameters such as power, speed, and focal length to accommodate the unique characteristics of each material, ensuring consistent quality in the cutting process.

Conclusion:

In the realm of die making, material versatility is key to unlocking a world of possibilities. Our Die Making Laser Cutting Machine offers a wide range of capabilities, allowing die makers to explore diverse materials without compromising on precision. While certain limitations exist, an understanding of these considerations empowers die makers to harness the full potential of our machine, pushing the boundaries of creativity and innovation in the art and science of die production.