Enhancing Steel Metal Stamping Components: Exploring Surface Finish Options

2024-03-13

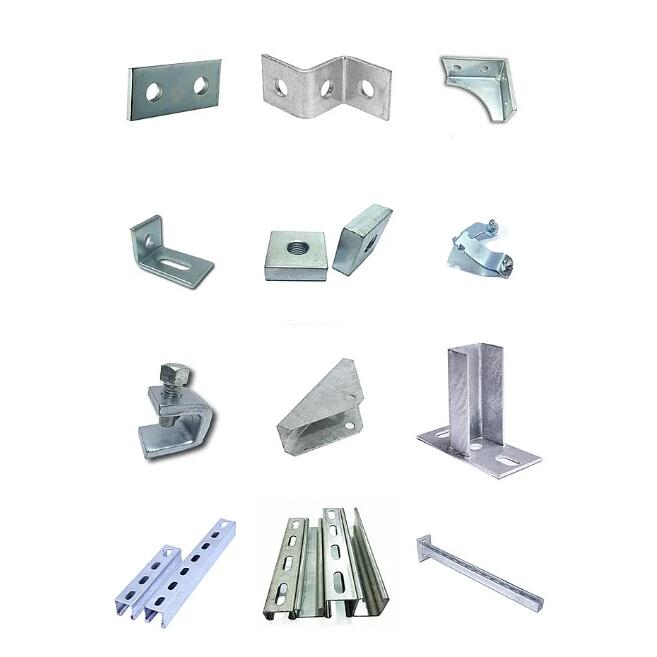

Steel metal stamping components play a vital role in various industries, serving as integral parts of machinery, automotive systems, appliances, and more. Beyond their functional properties, the surface finish of stamped steel components can significantly impact their aesthetics, corrosion resistance, and overall performance. In this blog, we'll explore the diverse range of surface finish options available for steel metal stamping components, highlighting their characteristics, applications, and benefits.

Importance of Surface Finishes:

Surface finishes not only enhance the appearance of stamped steel components but also provide crucial functional benefits such as corrosion protection, wear resistance, and improved lubricity. The choice of surface finish depends on factors such as the component's application, environmental exposure, performance requirements, and desired aesthetic appeal.

Common Surface Finish Options:

1. Plating:

Plating is a popular surface finishing technique that involves electroplating or immersion of the stamped steel component in a thin layer of metal, such as zinc (galvanizing), nickel, chrome, or tin. Plating offers excellent corrosion resistance, aesthetic appeal, and durability, making it suitable for automotive parts, fasteners, and decorative components.

2. Painting and Powder Coating:

Painting and powder coating are applied as protective layers over the surface of stamped steel components to enhance corrosion resistance, durability, and aesthetics. Paints and powder coatings come in a variety of colors, textures, and formulations, allowing for customization to meet specific design requirements and aesthetic preferences.

3. Anodizing:

Anodizing is a surface treatment process commonly used for aluminum components but can also be applied to certain types of steel alloys. Anodizing creates a durable oxide layer on the surface of the steel, providing enhanced corrosion resistance, abrasion resistance, and electrical insulation properties. Anodized finishes are commonly used in architectural applications, electronics, and consumer goods.

4. Passivation:

Passivation is a chemical treatment process that removes free iron and other surface contaminants from stainless steel components, improving corrosion resistance and enhancing surface cleanliness. Passivated finishes are commonly used in medical devices, food processing equipment, and aerospace components where cleanliness and corrosion resistance are critical.

5. Electropolishing:

Electropolishing is an electrochemical surface finishing process that removes surface imperfections, micro-burrs, and embedded contaminants from stamped steel components. Electropolishing produces a smooth, bright, and uniform surface finish, improving corrosion resistance, cleanliness, and aesthetic appearance. It is commonly used in medical, pharmaceutical, and high-purity applications.

6. Hot-Dip Galvanizing:

Hot-dip galvanizing involves immersing the stamped steel component in a bath of molten zinc to create a protective zinc coating on the surface. Hot-dip galvanizing provides excellent corrosion protection, abrasion resistance, and longevity, making it suitable for outdoor applications, structural components, and utility poles.

7. Mechanical Finishes:

Mechanical finishes, such as grinding, brushing, or polishing, are used to remove surface imperfections, burrs, and sharp edges from stamped steel components. Mechanical finishes improve surface smoothness, appearance, and cleanliness, enhancing the overall quality and functionality of the components.

Conclusion:

The surface finish of steel metal stamping components plays a crucial role in determining their performance, durability, and aesthetic appeal. By selecting the appropriate surface finish based on application requirements, manufacturers can enhance corrosion resistance, improve functionality, and elevate the visual impact of stamped steel components across a wide range of industries and applications. As an integral part of the manufacturing process, surface finishing techniques offer endless possibilities for customization, protection, and optimization of stamped steel components to meet the evolving needs of modern industry.