How are mesh conveyor wire belts constructed and woven

2023-10-31

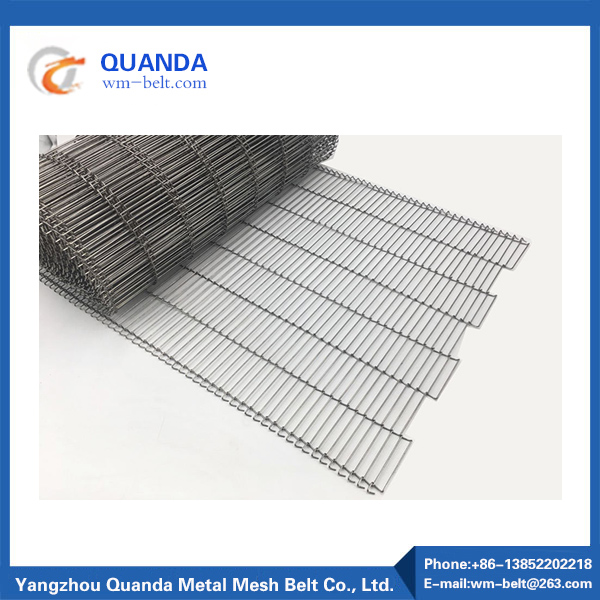

Mesh conveyor wire belts are constructed through a weaving or interlocking process where metal wires are arranged and linked together to create a continuous, flexible conveyor belt with an open mesh pattern. The specific construction and weaving methods can vary based on the design and the intended application. Here's a general overview of how mesh conveyor wire belts are constructed and woven:

1. Wire Selection:

- The process begins with selecting the appropriate type and gauge of metal wire based on the desired belt strength, flexibility, and resistance to environmental factors (e.g., heat, corrosion). Common wire materials include stainless steel, carbon steel, Inconel, Monel, and more.

2. Wire Straightening:

- The selected wires are often straightened to ensure uniformity and ease of weaving. Straightening may involve a mechanical or automated process to remove any kinks or bends.

3. Weaving Process:

- The weaving process typically involves a series of warp wires (running lengthwise) and weft wires (running widthwise) interlocking to create the mesh pattern. Several common weaving methods are used, including:

- Balanced Weave: In this method, the number of warp wires equals the number of weft wires per unit length, resulting in a balanced and sturdy mesh.

- Compound Balanced Weave: This weaving method uses a combination of thick and thin wires to create a balanced and robust design.

- Chain Weave: Chain weave belts consist of alternating left and right spiral wires, creating a flexible and flat surface suitable for lighter-duty applications.

- Flat-Flex Weave: This weave combines flattened wire spirals for a more open mesh design, making it suitable for applications like cooling or drying.

4. Joining or Welding:

- Depending on the design, the ends of the wires are often joined or welded together to create a continuous loop. This joining can be done using various methods, including looped wire pins, clinched loops, or welding techniques.

5. Edge Reinforcement:

- To prevent the edges of the belt from fraying or becoming damaged, edge reinforcement may be added. This reinforcement can consist of either crimped or welded edges.

6. Finishing:

- The finished mesh conveyor wire belt may undergo additional processes such as cleaning, surface treatments (e.g., passivation for stainless steel), or coatings, depending on the application's requirements.

The choice of weaving pattern and wire materials is crucial to tailor the mesh conveyor wire belt for specific applications. The resulting belt offers characteristics such as flexibility, durability, heat resistance, and open mesh patterns that can efficiently transport products, whether in the food industry, heat treatment processes, or other industrial applications.