Illuminating Precision: The Anatomy of a High-Power Fiber-Coupled Laser System

2023-12-04

Introduction:

Behind the brilliance of a high-power fiber-coupled laser lies a sophisticated arrangement of components working in harmony to deliver precision and power. This technological marvel seamlessly integrates high-power laser sources with the flexibility of optical fibers, creating a versatile tool that finds applications across industries. In this blog post, we'll delve into the basic structure and key components that constitute a high-power fiber-coupled laser system, unraveling the intricacies that make these systems a driving force in laser technology.

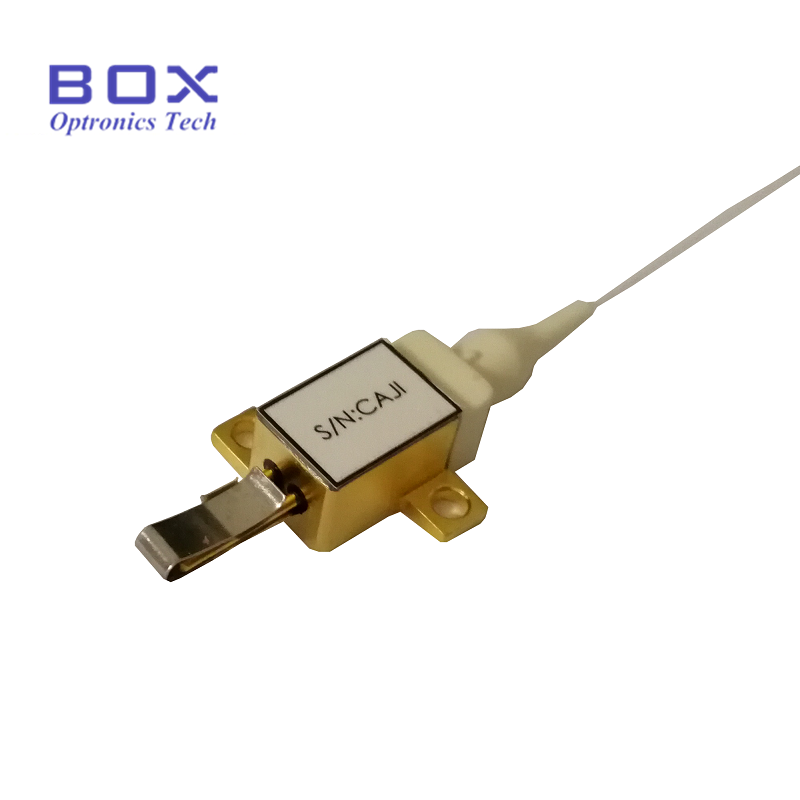

1. High-Power Laser Source:

At the heart of the system resides the high-power laser source. This can be a diode laser, a fiber laser, or a solid-state laser, capable of generating intense beams of light. The power output of these lasers can range from several watts to kilowatts, depending on the application requirements.

2. Coupling Optics:

Coupling optics serve as the bridge between the high-power laser source and the optical fiber. These optics play a crucial role in efficiently transferring the laser light into the fiber, optimizing the coupling efficiency, and ensuring the preservation of beam quality during the transition.

3. Optical Fiber:

The optical fiber is a core component of the system, serving as the conduit for the laser beam. Optical fibers come in various types, including single-mode and multi-mode fibers, each tailored to specific applications. These fibers are chosen based on factors such as beam quality requirements, power levels, and the desired wavelength.

4. Fiber Connectors:

To establish a reliable connection between the laser source and the optical fiber, fiber connectors are used. These connectors ensure proper alignment and efficient transfer of laser light. Common connector types include FC (Fiber Connector), SMA (SubMiniature version A), and ST (Straight Tip).

5. Collimating Optics:

Collimating optics are often employed to shape and align the laser beam as it exits the optical fiber. This step is crucial to maintain the beam quality and enable precise control over the beam's characteristics, such as divergence and focus.

6. Beam Expander (Optional):

In some applications, a beam expander may be included in the system. This optical component magnifies the diameter of the laser beam, reducing its divergence. Beam expanders are particularly useful when applications demand a larger spot size or extended focal length.

7. Fiber Termination and Delivery System:

The optical fiber terminates at a specific point where the laser beam is delivered to the target or processing area. This termination point may involve additional optics or focusing elements depending on the application, ensuring that the laser beam meets the desired specifications at the point of use.

8. Cooling System:

Given the high-power nature of these laser systems, an effective cooling system is essential to dissipate the heat generated during operation. Cooling methods may include air or liquid cooling systems, ensuring the stability and longevity of the laser source.

9. Control and Monitoring Electronics:

Control and monitoring electronics form the brains of the system, overseeing the operation of the high-power fiber-coupled laser. These electronics may include control units, interface modules, and monitoring systems that enable users to adjust parameters, monitor performance, and ensure the system operates within specified limits.

Conclusion:

The synergy of high-power laser sources with the flexibility of optical fibers in a fiber-coupled laser system is a testament to the ingenuity of laser technology. Understanding the basic structure and components of these systems unveils the complexity behind their seemingly effortless precision. As high-power fiber-coupled lasers continue to evolve, pushing the boundaries of what's achievable, their impact on industries ranging from manufacturing and healthcare to research and defense is destined to grow, ushering in a new era of precision and efficiency in laser applications.