Mastering Variability: How Edge Banding Cells Tackle Material Dimensions and Specifications

2024-03-15

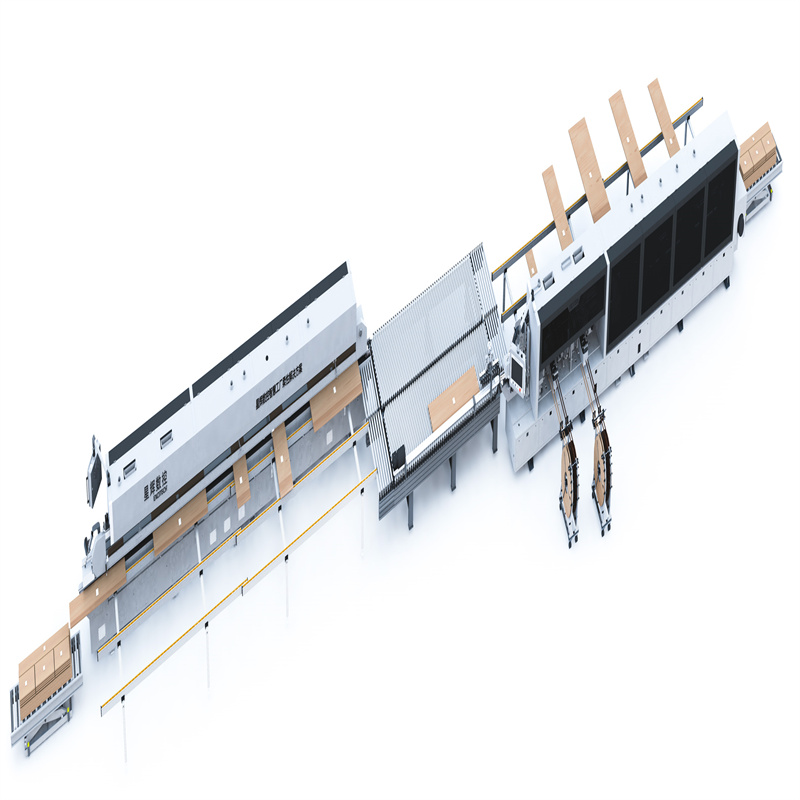

In the realm of woodworking and furniture manufacturing, precision is paramount. Every piece must meet exacting standards, regardless of variations in material dimensions and specifications. This challenge is particularly pronounced in edge banding operations, where consistency and accuracy are essential for achieving seamless finishes. Fortunately, edge banding cells are equipped with sophisticated technology and innovative solutions to handle these variations effectively. In this blog, we'll explore how edge banding cells tackle variations in material dimensions and specifications with finesse and precision.

1. Advanced Vision Systems:

Edge banding cells are equipped with advanced vision systems that play a crucial role in handling variations in material dimensions and specifications. These systems utilize high-resolution cameras and sensors to precisely identify workpiece dimensions, edge profiles, and alignment requirements. By capturing detailed images and measurements, the vision systems enable the edge banding cell to adjust its operations dynamically, ensuring precise edge banding regardless of material variations.

2. Adaptive Software Algorithms:

To accommodate variations in material dimensions and specifications, edge banding cells utilize adaptive software algorithms that can analyze and interpret data in real-time. These algorithms are programmed to recognize patterns, detect deviations from standard specifications, and make automatic adjustments to compensate for variations. By continuously adapting to changing conditions, the edge banding cell maintains consistent quality and performance across a wide range of materials and specifications.

3. Flexible Machine Configurations:

Edge banding cells are designed with flexibility in mind, allowing for customizable machine configurations to accommodate variations in material dimensions and specifications. Adjustable settings such as feed speed, pressure, and temperature can be fine-tuned to optimize edge banding performance based on specific material properties and requirements. Additionally, modular designs allow for easy integration of additional components or accessories to enhance adaptability and versatility.

4. Precision Cutting and Trimming Tools:

Precision cutting and trimming tools are essential components of edge banding cells, enabling precise shaping and finishing of edges to meet exacting specifications. These tools are equipped with advanced features such as programmable cutting paths, variable speed controls, and automatic tool changes to accommodate variations in material dimensions and specifications. By leveraging the latest technology in cutting and trimming, edge banding cells ensure consistent and uniform results regardless of material variability.

5. Real-time Monitoring and Feedback:

Edge banding cells incorporate real-time monitoring and feedback mechanisms to continuously assess performance and detect deviations from desired specifications. Sensors and monitoring devices measure key parameters such as material thickness, temperature, and adhesive application, providing instant feedback to the control system. If any discrepancies are detected, the edge banding cell can make immediate adjustments to maintain optimal performance and ensure adherence to specifications.

6. Operator Intervention and Manual Overrides:

While edge banding cells are highly automated, they also allow for operator intervention and manual overrides when necessary. Operators can monitor the process closely and intervene to make adjustments or corrections based on their expertise and judgment. Manual overrides provide an additional layer of control and flexibility, allowing operators to fine-tune settings or address unexpected variations in material dimensions or specifications on the fly.

In conclusion, edge banding cells are equipped with a variety of advanced technologies and innovative solutions to handle variations in material dimensions and specifications with precision and accuracy. From advanced vision systems and adaptive software algorithms to flexible machine configurations and precision cutting tools, these systems are designed to adapt to changing conditions and ensure consistent quality across a wide range of materials and specifications. By mastering variability, edge banding cells empower manufacturers to achieve seamless finishes and deliver exceptional products that meet the highest standards of craftsmanship and quality.