Unveiling Craftsmanship: Bathroom Products Shaped by Chassis Moulds

2023-11-13

Introduction:

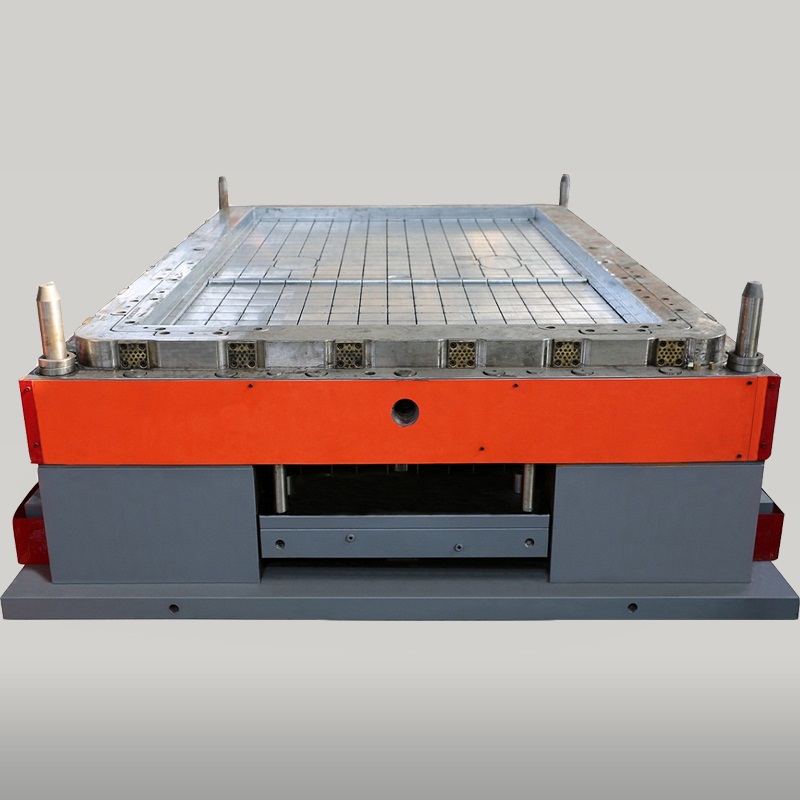

In the bustling realm of bathroom manufacturing, precision and innovation converge to shape the components that adorn our private sanctuaries. At the heart of this process lies the chassis mould, a versatile tool that transforms raw materials into refined bathroom elements. In this blog, we explore the diverse types of bathroom products and components that are typically produced using chassis moulds, showcasing the craft behind the fixtures that enhance our daily rituals.

1. Sinks and Basins:

One of the most common products crafted with chassis moulds is the sink or basin. The sleek curves, defined edges, and intricate shapes of various sink designs are made possible through the precision of chassis moulds, allowing manufacturers to cater to a broad spectrum of styles and preferences.

2. Faucet Handles and Spouts:

The handles and spouts of faucets are intricately molded using chassis moulds. Whether it's a modern minimalist design or a classic, ornate style, the precision afforded by these moulds ensures the accurate reproduction of each detail, resulting in functional and aesthetically pleasing faucet components.

3. Shower Heads:

The diversity of shower head designs, from rainfall to handheld options, is made possible through chassis moulds. The precision in molding allows manufacturers to create products that provide a range of water delivery options, contributing to a customizable and enjoyable shower experience.

4. Toilet Seats:

Chassis moulds play a crucial role in shaping the ergonomic and visually appealing designs of toilet seats. From standard designs to those with advanced features like soft-close mechanisms, the versatility of chassis moulds enables the production of a wide array of toilet seat styles.

5. Bathtubs and Shower Enclosures:

The larger fixtures in bathrooms, such as bathtubs and shower enclosures, are often produced using chassis moulds. The precision in mould design allows for the creation of various shapes, sizes, and configurations, providing consumers with a diverse range of options to suit their space and preferences.

6. Soap Dishes and Dispensers:

Chassis moulds contribute to the creation of smaller but essential bathroom accessories, including soap dishes and dispensers. The intricate details and functional designs of these components are achieved through the precision afforded by moulding techniques.

7. Toothbrush Holders and Tumblers:

Bathroom accessories like toothbrush holders and tumblers also undergo the moulding process. Chassis moulds enable the production of these small but essential items with consistent quality and design, adding a touch of functionality and style to bathroom spaces.

8. Bathroom Mirrors and Frames:

Even elements like bathroom mirrors and frames benefit from chassis moulds. The precision in mould design allows for the creation of frames with intricate details, enhancing the overall aesthetic appeal of mirrors and contributing to the visual harmony of bathroom spaces.

Conclusion:

The world of bathroom manufacturing is a tapestry woven with precision, creativity, and innovation. Chassis moulds serve as the artisan's brush, shaping the diverse array of bathroom products and components that elevate our daily rituals. From the elegance of sinks to the functionality of shower heads, the meticulous craftsmanship facilitated by chassis moulds enriches our bathroom spaces with a harmonious blend of form and function.