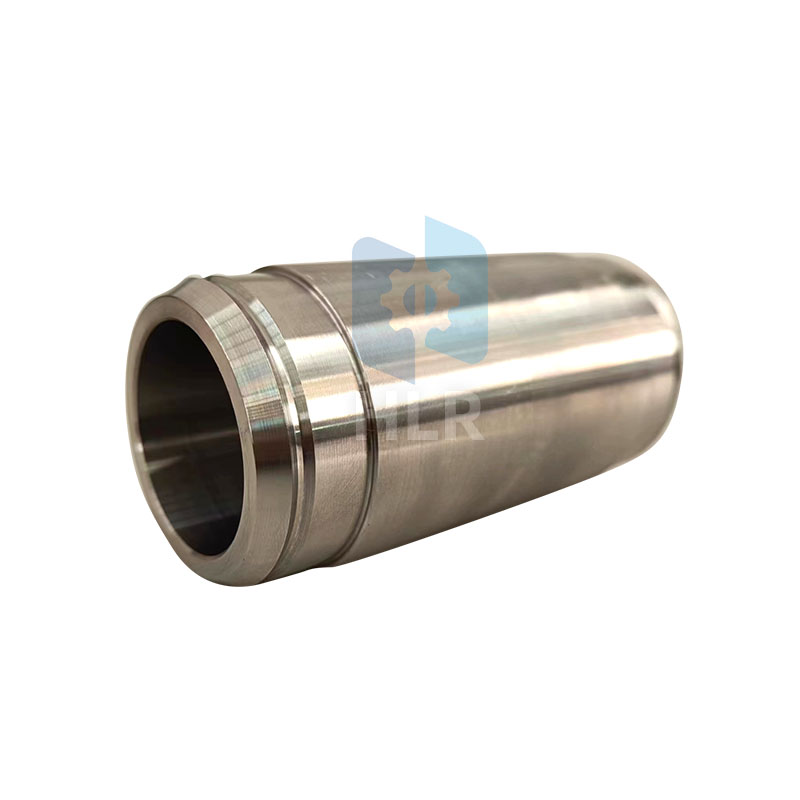

Unveiling the Superiority: Advantages of Sealed Stainless Steel Cylinder Liners

2024-02-20

In the realm of engine design, where performance, efficiency, and durability are paramount, the choice of materials for critical components can make all the difference. Among the options available, sealed stainless steel cylinder liners stand out as a pinnacle of excellence, offering a multitude of advantages over traditional materials such as cast iron or aluminum. Let's explore why sealed stainless steel cylinder liners have become the preferred choice for demanding applications in automotive, aerospace, marine, and industrial sectors.

Unmatched Durability and Strength

Stainless steel, renowned for its exceptional strength and durability, outshines both cast iron and aluminum in terms of longevity and resilience. Sealed stainless steel cylinder liners are engineered to withstand the rigors of high-performance engines, resisting wear, corrosion, and thermal stress with unparalleled reliability. This superior durability translates to extended service life, reduced maintenance costs, and enhanced operational efficiency.

Corrosion Resistance

While cast iron and aluminum are susceptible to corrosion, especially in harsh operating environments or when exposed to corrosive fluids, stainless steel cylinder liners offer robust protection against degradation. The inherent corrosion resistance of stainless steel, bolstered by alloying elements such as chromium, ensures long-term integrity and performance, even in corrosive conditions. This resistance to corrosion minimizes the risk of leaks, contamination, and premature failure, enhancing the overall reliability of the engine.

Superior Heat Dissipation

Efficient heat dissipation is crucial for maintaining optimal engine performance and preventing overheating-related issues. Sealed stainless steel cylinder liners excel in dissipating heat generated during combustion, thanks to their high thermal conductivity and stability. Unlike aluminum, which has lower thermal conductivity, stainless steel efficiently transfers heat away from the combustion chamber, reducing thermal stress on engine components and promoting consistent operating temperatures.

Precision Engineering and Tight Tolerances

Sealed stainless steel cylinder liners are manufactured with precision engineering techniques to achieve tight tolerances and optimal piston-to-cylinder clearance. This meticulous craftsmanship ensures proper sealing, minimal friction, and optimal compression ratios, contributing to improved engine efficiency and power output. In contrast, cast iron and aluminum may exhibit greater dimensional variability, leading to potential issues such as piston slap, excessive wear, and reduced performance.

Versatility and Adaptability

Sealed stainless steel cylinder liners offer versatility and adaptability across a wide range of engine configurations and applications. Whether in high-performance racing engines, heavy-duty diesel engines, or marine propulsion systems, stainless steel cylinder liners can be tailored to meet specific performance requirements and environmental challenges. This flexibility makes them the preferred choice for demanding applications where reliability and performance are non-negotiable.

Conclusion

In the competitive landscape of engine design, the advantages of sealed stainless steel cylinder liners over traditional materials such as cast iron or aluminum are unmistakable. From unmatched durability and corrosion resistance to superior heat dissipation and precision engineering, stainless steel cylinder liners embody excellence in performance, reliability, and longevity. As automotive, aerospace, and industrial technologies continue to evolve, sealed stainless steel cylinder liners remain at the forefront of innovation, driving advancements in engine efficiency, sustainability, and performance.